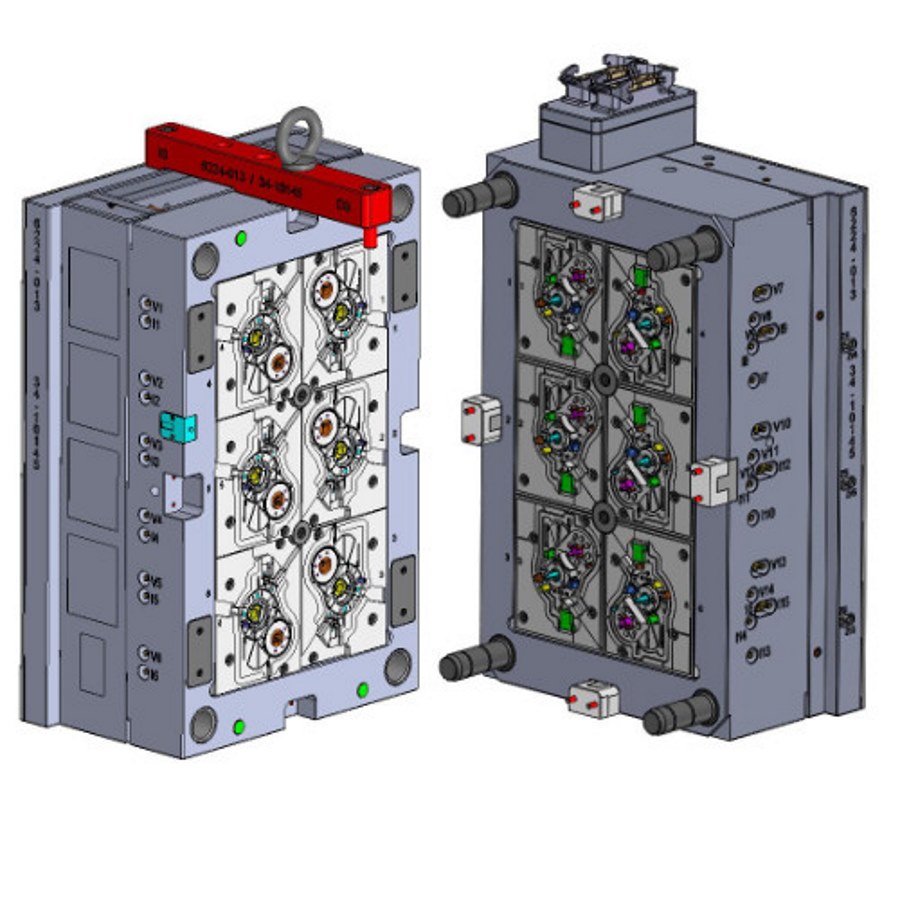

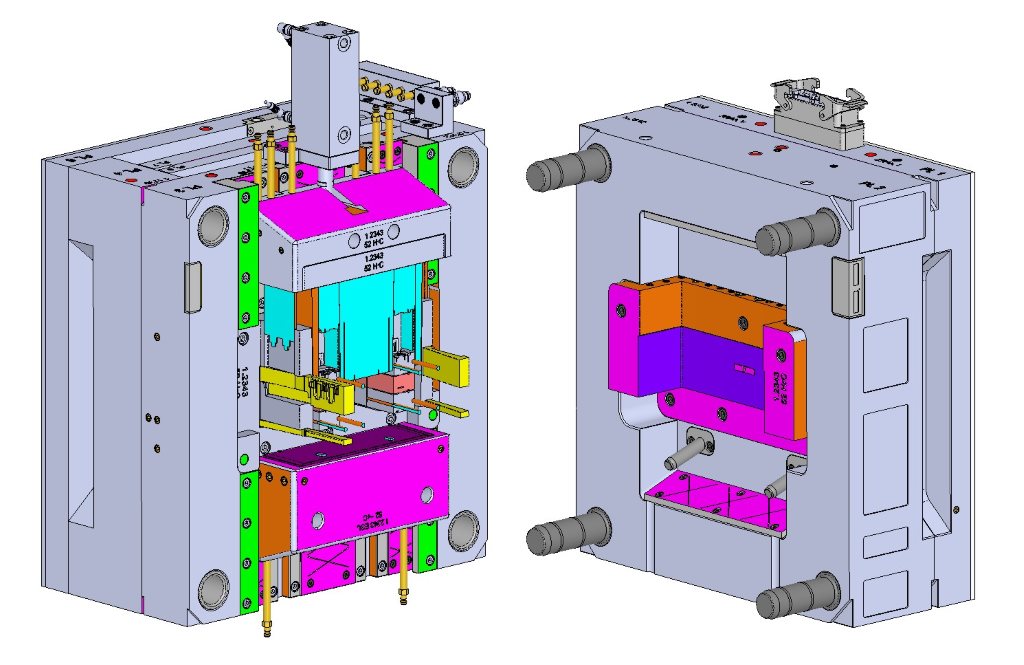

Construction of tools for plastic injection moulding

Quality plastic injection mould is a basic condition for a stable production and quality final plastic products.

With our experience in construction and technological optimisations, our tool or plastic injection mould can reduce the production costs.

Advanced solutions in the field of tempering and cooling reduce the cycle time of plastic injecting process. Reliable construction and tool design ensure a long service life.

In the concept phase, we focus on the optimal injection point and ejection system.

We construct tools for automotive industry, household appliances, technical products, packaging industry and others.

Special care is dedicated to state-of-the-art technological solutions in the phase of tool design. We follow the latest trends in tool manufacturing and implement them into our constructions.

In high productivity mould, we recommend the use of top class materials, such as HTCS 130 DC, Ampcoloy alloys and others.

We have vast experiences with constructions that contain complex mechanisms, such as sliders, inclined ejectors, hydraulic systems, unscrewing devices, pneumatic ejection, 3-plates systems, forced and two-stage ejections, valve gate hot nozzles, hot runner systems and so on.

We also have experiences with 2K – two component tools and IML – in mould labeling (IMD – in mould decoration) technology.