CAD Dizajn employs experts in the field of constructing and manufacturing plastic injection moulds. Many years of experiences are an assurance for a common success. At our work, we use Solidworks CAD software and also have many experiences with Catia CAD software. Our constructions are adapted to our customers’ machine park. Our experts’ teamwork is an assurance that the agreed time schedules are fully respected.

About company founder

Krunoslav Dubić, mag.ing.mech.

His contribution to the company are his vast experiences in production technologies and CAM expertise. Prior to preparation of the construction concept, he studies the customer’s machine park and adopts the constructions to the customer’s specifics.

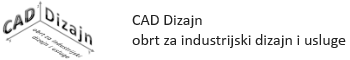

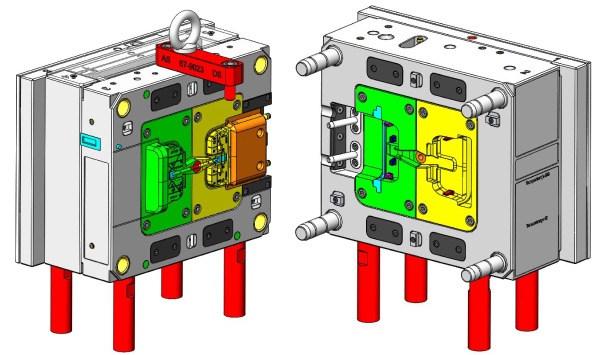

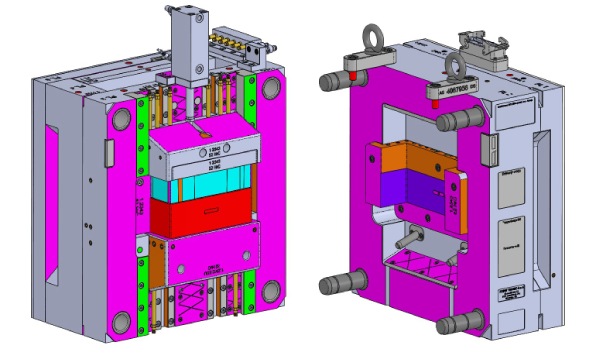

CONSTRUCTION

Construction of tools for plastic injection moulding is the core of our offer.

We construct tools for automotive industry, household appliances, technical products, packaging industry and others.

Special care is dedicated to state-of-the-art technological solutions in the phase of tool design. We follow the latest trends in tool manufacturing and implement them into our constructions.

Calculations for making offers

As the only one in the market we offer consulting in the field of making offer calculations for plastic injection moulds. We offer a complete service in preparing calculations. We have experiences with more than 500 tools in the field of preparing concepts and calculations. We also have our own database and software for preparing calculations.

Support

Beside construction, we also offer support in the process of designing and manufacturing plastic injection moulds:

- making of the concepts, DFM analyses, Moldflow simulations,

- thermography, analysis and proposals for optimisation of the current state of the tool,

- Konstruiranje elektrod in izdelovanje erodirnih načrtov,

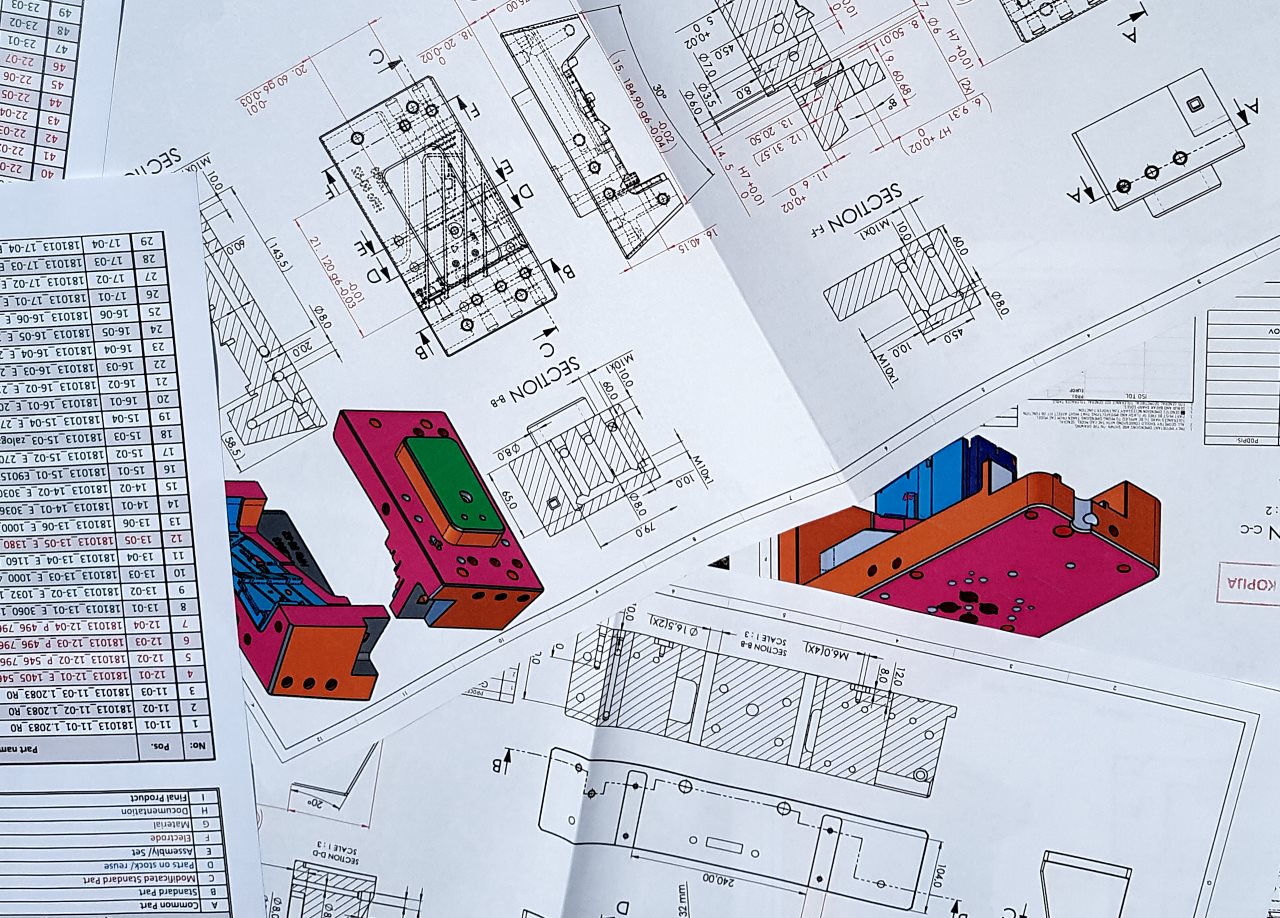

- construction of electrodes and EDM plans,

- preparation for wire erosion, turning and milling,

- manufacturing of complete 2D technical documentation,

- manufacturing of accurate BOM with suppliers list,

- colouring of 3D models according to the tolerances and surface quality demands as an alternative to the 2D documentation,

- manufacturing of maintenance manuals, technical mould requirements, etc.

Consulting

We offer consulting when selecting standard elements suppliers,

hot runner system suppliers, materials and services, such as heat treatment, local heat treatment, nitriding, chroming, special PVD coatings, etc.

We propose the most appropriate technological manufacturing of tool parts and, when needed, we organise cooperation of machining processes at our trusted tool shops.

We offer accurate Moldflow analyses, which are necessary in the concept phase of demanding projects.

With our partner we offer DLMS – laser sintering of conformal cooled mould parts.

.

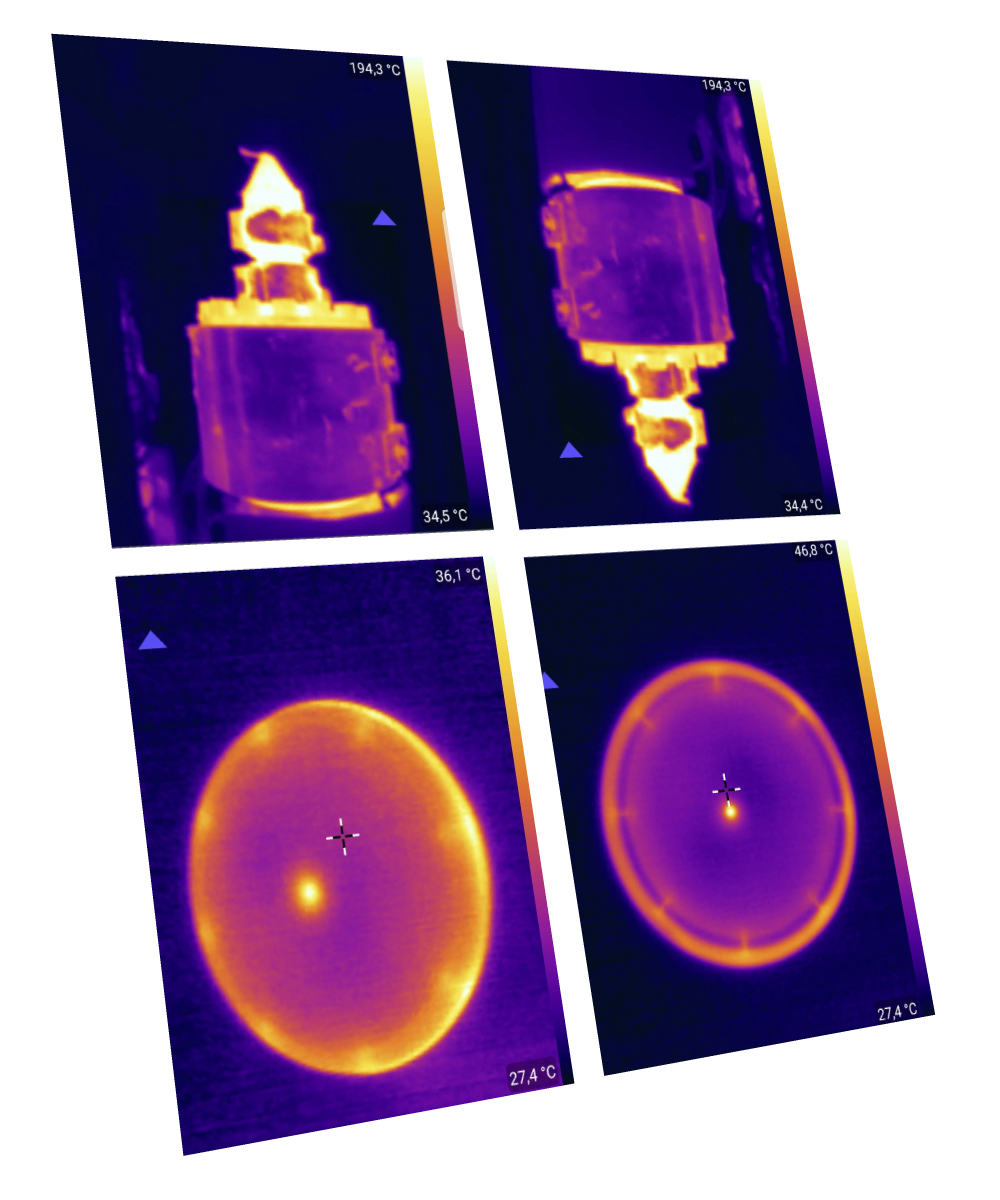

Thermography

We offer a complete service in the field of thermography with professional infrared camera FLIR.

With our professional infrared camera FLIR we analyse the current state of the plastic product, especially at manufacturing of repeated mould. We detect critical areas, which have a negative influence on the product quality and on the cycle time.

With the use of advanced technologies, we improve tempering at the target area and, therefore, we improve the quality of repeated mould.

We analyse the functioning of tempering and injection systems on the existing tool and advise on actions to reduce the cycle time.